Innovative copper and zinc recovery

Reducing climate impact

High replicability

About

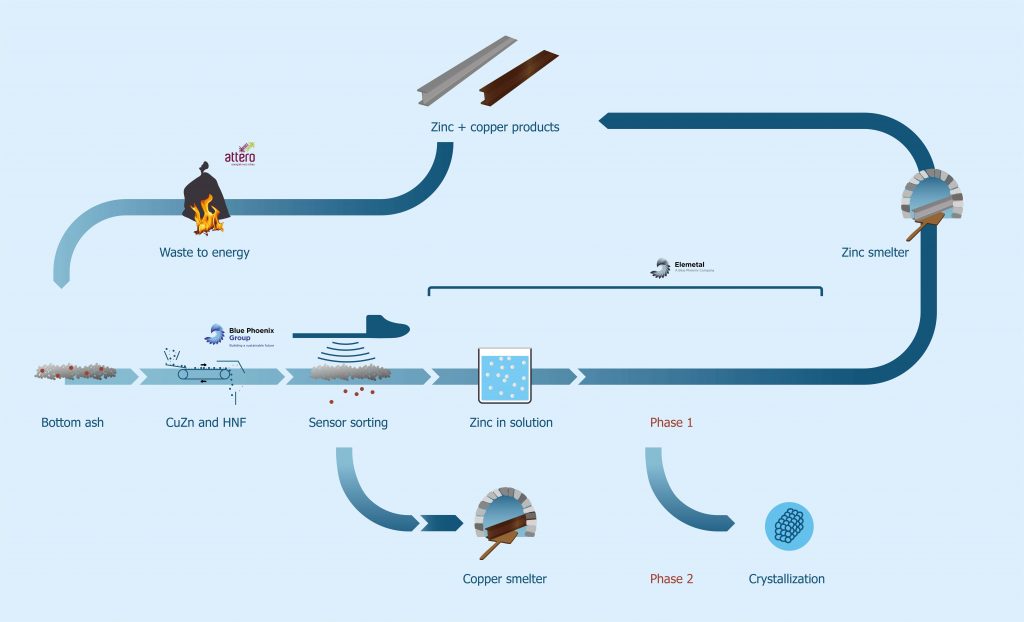

The idea of the project originated from the startup company Elemetal. As a spin-off from Delft Technical University Elemetal started with the development of . . .

Project

Waste-to-Energy is widely used in Europe for treatment of residual waste. After thermal treatment the waste is converted to electrical energy and two “main” types of residues: bottom ashes and fly ashes. One tonne of . . .

News & events

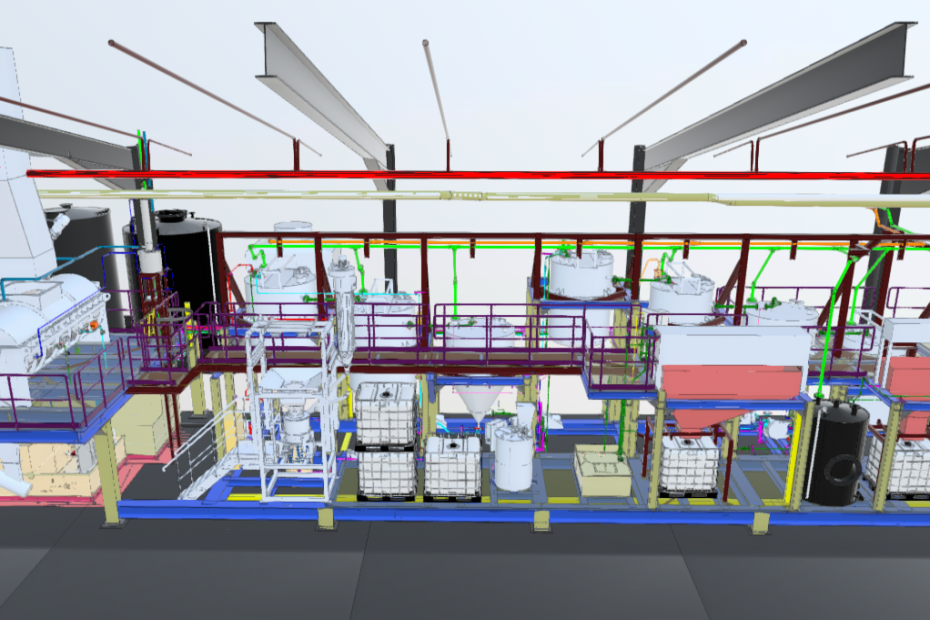

Elemetal is pleased to inform you that on the 10th of January 2020 Elemetal signed a 3-years rental contract for a new demonstration location at PlantONE, Merseyweg 10, Botlek, The Netherlands. PlantONE is . . .